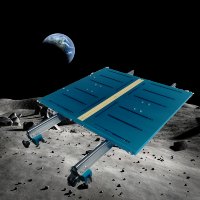

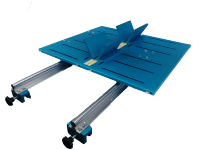

Sliding table BST

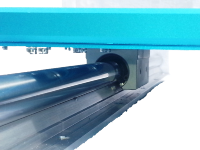

The sliding table BST is a must for every bandsaw. Easy to mount on existing square guide of the fence. The sliding table is guided on two solid, maintenance-free and resistant to dirt linear guides. The low overall height ensures no restriction in the cutting height. Accessories for safe crosscutting of round workpieces, for cutting of upright standing workpieces, crosscutting of upright standing workpieces, longitudinal fence and mitre fence are optionally available. With the optionally available T-shaped sliding blocks which are mounted in the table it's also possible to mount own devices without problems.

Technical data:

- Dimension support plate left Hand side of the sawblade: 500 x 300 mm

- Dimension support plate Right Hand side of the sawblade: 500 x 300 mm

- Cutting length: approx. 500 mm minus sawblade width (depending on the size of the machine table)

- Length linear guides: 800 mm

- Overall height over machine table: 70 mm item-no. 13700

Longitudinal fence standard BSL 1

For lengthwise cutting, length 385 mm, height 140 mm, easy montage on the sliding table with two screws and T-shaped sliding blocks (4 pieces) which are included in the delivery with the longitudinal fence. Cutting width max. 220 mm. item-no. 13702

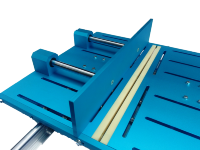

Longitudinal fence deluxe BSL 2

For lengthwise cutting, length 527 mm, height 100 mm, guided in two round guides, easy clamping. Easy montage with 4 screws from the bottom of the sliding table. Depending on the desired cutting width there are two fixation positions available. Cutting width at pos. 1 max. 190 mm (with a cutting width of the machine of 450 mm), at pos. 2 max. 225 mm (with a cutting width of the machine of 485 mm). item-no. 13704

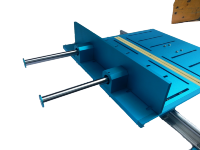

Edgewise fence BSH

For safe cutting of upright standing workpieces, height 150 mm, width 150 mm, 2 pieces. Easy montage on the sliding table through 8 T-shaped sliding blocks which are included in the delivery of the edgewise fence. Further T-shaped sliding blocks optionally available. item-no. 13701

Round timber fence BSR

For safe length- and crosswise cutting of round and square timber. Easy montage on the sliding table through 8 T-shaped sliding blocks which are included in the delivery of the round timber fence. Further T-shaped sliding blocks optionally available. item-no. 13703

Bandsaw guide BSF

The bandsaw guide is the most important element on a bandsaw. For this reason our bandsaw guide BSF is made of precise worked anodized aluminium.

The hardened side roller are conical and are running in maintanence-free sintered bushes.

The maintanence-free, hardened and ball bearing back roller is standard, resists heaviest use and is suitable to cut cast iron and aluminium.

Thanks to the easy assembly, the bandsaw guide is mountable on almost every bandsaw.

The hardened running tread of the side- and back roller guarantees an use for years and are easy to change. The fixing parts are included in the delivery (delivery also possible without fixing parts).

Technical data:

Upper bandsaw guide BSF 1

for wheel diameter 400 - 600 mm

for blade width from 5 - 30 mm item-no. 11500

Lower bandsaw guide BSF 1

for wheel diameter 400 - 600 mm

for blade width from 5 - 30 mm item-no. 11501

Upper bandsaw guide BSF 2

for wheel diameter 600 - 900 mm

for blade width from 5 - 40 mm item-no. 11502

Lower bandsaw guide BSF 2

for wheel diameter 600 - 900 mm

for blade width from 5 - 40 mm item-no.11503

spareparts for lower bandsaw guide BSF 2

designation | item-no. BSF 2 | |

bolt for back roller | 12800 | |

Disc for back roller | 12801 | |

runnig tread, hardened for back roller | 12802 | |

bearing for back roller | 12803 | |

locking ring for back roller | 12804 | |

screws (4 pieces) for back roller | 12705 | |

grooved bolt | 12806 | |

holder | 12809 | |

side roller with bearing sleeve and housing | 12826 | |

holder plate for housing side roller | 12824 | |

holder plate for back roller BSF | 12825 | |

dowel pin | 12718 | |

hexagon socket head cap screw | 12819 | |

knurled screw for clamping back roller and grooved bolt | 12721 |

spareparts for upper bandsaw guide BSF 2

designation | item-no. BSF 2 | |

bolt for back roller | 12800 | |

disc for back roller | 12801 | |

running tread, hardened for ack roller | 12802 | |

bearing for back roller | 12803 | |

locking ring for back roller | 12804 | |

screws (4 pieces) for back roller | 12705 | |

grooved bolt | 12806 | |

clamping piece with thread | 12807 | |

clamping piece without thread | 12808 | |

holder | 12809 | |

side roller with bearing sleeve and housing | 12825 | |

mounting plate BSF | 12811 | |

dowel pin | 12718 | |

hexagon socket head cap screw | 12819 | |

knurled screw for clamping back roller and grooved bolt | 12721 |

Back roller BSR

Back roller BSR for all common bandsaw guides such as BSF, GL, GSP, Panhans and HEMA. All back roller have ball bearings, resist heaviest use and is suitable to cut cast iron and aluminium.

List of available back roller:

Wheel diam. | Bolt diam. | Designation | Total length | Item-no. | Suitable for the following brands |

35 mm | 16 mm | BSR 0 top | 61,6 mm | 12600 | Panhans 1055 size 1 top |

35 mm | 16 mm | BSR 0 bottom | 61,6 mm | 12601 | Panhans 1055 size 1 bottom |

40 mm | 16 mm | BSR 1 top | 60,1 mm | 12602 | BSF 1 top Panhans 1055 size 2 top Panhans APA II size 1 top HEMA FS 40 top |

40 mm | 16 mm | BSR 1 bottom | 60,1 mm | 12603 | BSF 1 bottom Panhans 1055 size 2 bottom Panhans APA II size 1 bottom HEMA FS 40 bottom |

58 mm | 22 mm | BSR 2 top | 91,5 mm | 12604 | BSF 2 top Panhans 1055 size 3 top Panhans APA II size 2 top HEMA FS 58 top |

58 mm | 22 mm | BSR 2 bottom | 95,5 mm | 12605 | BSF 2 bottom Panhans 1055 size 3 bottom Panhans APA II size 2 bottom HEMA FS 58 bottom |

58 mm | 20 mm | BSR 3 top | 76,4 mm | 12606 | Panhans Si-Ho size 3 top |

58 mm | 20 mm | BSR 3 bottom | 76,4 mm | 12607 | Panhans Si-Ho size 3 bottom |

35 mm | 20 mm | BSR 4 | 61,1 mm | 12608 | GL 456 and GSP 456 |

45 mm | 20 mm | BSR 5 | 76,4mm | 12609 | GSP 789 |

50 mm | 20 mm | BSR 6 | 76,4 mm | 12610 | GL 789 |

Pressing device BSA 1

Pressing device for safe cutting of narrow and long strips. The workpiece will be pressed against the existing fence through a spring and it can be pushed with a push stick for a safe cut. Easy to mount on existing square guide of the fence (only available for square guide). item-no. 16501

Pressing and protecting device BSA 2 item-no. 15501

suitable for almost every bandsaw up to a max. sawblade width of 90 mm

Rubber cork BSG

Rubber cork for easy repairs of bandsaw wheels at defect rubber.

Material sold by meter:

width | item-no. |

rubber cork 30 mm | 18500 |

rubber cork 35 mm | 18501 |

rubber cork 40 mm | 18502 |

rubber cork 45 mm | 18503 |

rubber cork 50 mm | 18504 |

rubber cork 55 mm | 18505 |

Custom-fit for respective wheel diameter:

Wheel diameter

| Item-no. |

Wheel diameter

| Item-no. | |

300x30 mm | 18600 | 600x45 mm | 18613 | |

300x35 mm | 18601 | 600x50 mm | 18614 | |

300x40 mm | 18602 | 700x40 mm | 18615 | |

400x30 mm | 18603 | 700x45 mm | 18616 | |

400x35 mm | 18604 | 700x50 mm | 18617 | |

400x40 mm | 18605 | 700x55 mm | 18618 | |

500x30 mm | 18606 | 800x40 mm | 18619 | |

500x35 mm | 18607 | 800x45 mm | 18620 | |

500x40 mm | 18608 | 800x50 mm | 18621 | |

500x45 mm | 18609 | 800x55 mm | 18622 | |

600x30 mm | 18610 | 900x40 mm | 18623 | |

600x35 mm | 18611 | 900x45 mm | 18624 | |

600x40 mm | 18612 | 900x50 mm | 18625 | |

900x55 mm | 18626 |

Contact power glue item-no. 18700

GEL contact glue for rubber cork. 1 tin approx. 640 gr., suitable for approx. 3 bandages up to 800 mm wheel diameter.

Butt welding machine for bandsaw blades model VC-4 item-no. 17500

Butt welding machine for bandsaw blades, metal bands in general. Reliable, inexpensive and very easy to use. Manual welding and annealing. Shear included

Technica data:

Width bandsaw blade min. | 10 mm |

Width bandsaw blade max. | 40 mm |

Thickness bandsaw blade min. | 0,5 mm |

Thickness bandsaw blade max. | 1,2 mm |

Cross section max. | 32 mm^2 |

Power | 4,5 kW |

Voltage | 400 V |

Dimensions | B520xT490xH320 mm |

Net weigh | ca. 51 kg |

Packing dimensions | B800xT600xH500 mm |

Gross weight | ca. 67 kg |

Butt welding machine for bandsaw blades model VC-3 item-no. 17501

Butt welding machine for bandsaw blades, metal bands in general. Reliable, inexpensive and very easy to use. Manual weldingad annealing. Shear inluded

Technica data:

Width bandsaw blade min. | 5 mm |

Width bandsaw blade max. | 30 mm |

Thickness bandsaw blade min. | 0,5 mm |

Thickness bandsaw blade max. | 1,0 mm |

Cross section max. | 24 mm^2 |

Power | 4,0 kW |

Voltage | 400 V |

Dimensions | B520xT490xH320 mm |

Net weight | ca. 36 kg |

Packing dimensions | B800xT600xH500 mm |

Gross weight | ca. 52 kg |

Butt welding machine for badsaw blades model VCE-40 with electronic control of welding curret item-no. 17502

Butt welding machine with electronic control of welding and annealing current. Evolution of it's relevant manual version, it allows a greater sensitivity during the welding and annealing operations of thin bandsaw blades and metal bands. Shear included.

Technical data:

Width bandsaw blade min. | 10 mm |

Width bandsaw blade max. | 40 mm |

Thickness bandsaw blade min. | 0,5 mm |

Thickness bandsaw blade max. | 1,2 mm |

Cross section max. | 32 mm^2 |

Power | 4,5 kW |

Voltage | 400 V |

Dimensions | B520xT490xH320 mm |

Net weight | ca. 51 kg |

Packing dimensions | B800xT600xH500 mm |

Gross weight | ca. 67 kg |

Butt welding machine for badsaw blades model VCE-30 with electronic control of welding curret item-no. 17503

Butt welding machine with electronic control of welding and annealing current. Evolution of it's relevant manual version, it allows a greater sensitivity during the welding and annealing operations of thin bandsaw blades and metal bands. Shear included.

Technical data:

Width bandsaw blade min. | 5 mm |

Width bandsaw blade max. | 30 mm |

Thickness bandsaw blade min. | 0,5 mm |

Thickness bandsaw blade max. | 1,0 mm |

Cross section max. | 24 mm^2 |

Power | 4,0 kW |

Voltage | 400 V |

Dimensions | B520xT490xH320 mm |

Net weight | ca. 35 kg |

Packing dimensions | B800xT600xH500 mm |

Gross weight | ca. 51 kg |

Sharpening and Setting machine AM 70 item-no. 17504

Sharpening machine with setting machine. Automatic work cycle. Can sharpen bandsaw and circular saw blades ad set bandsaw blades only. Can sharpen all triangular profiles even those which have some space between teeth. Possibility to choose the type of sharpening: tooth front only or front and back. Allowing the independent adjustments of the feed pitch, of the grinding wheel working depth and the entry/exit speed. It's vertical design was studied to require little space and bear high workloads. Solid and reliable. Provided with the rod and roller to support saw blades to be sharpened.

Technical data:

Sharpening bandsaw blades | Sharpening circular saw blades | |||

Teeth profile | Triangular | Teeth profile | Triangular | |

Thickness bandsaw blade min. | 0,5 mm | Thickness circular saw blade min. | 1 mm | |

Thickness bandsaw blade max. | 1,5 mm | Thickness circular saw blade max. | 3 mm | |

Width bandsaw blade min. | 10 mm | Boring circular saw blade min. | 20 mm | |

Width bandsaw blade max. | 60 mm | Boring circular saw blade max. | 50 mm | |

Sharpening pitch min. | 5 mm | Diam. circular saw blade min. | 110 mm | |

Sharpening pitch max. | 30 mm | Diam. circular saw blade max. | 600 mm | |

Sharpening speed | 54 teeth/ min | Sharpening pitch min. | 5 mm | |

Sharpening pitch max. | 15 mm | |||

Sharpening speed | 54 teeth/ min | |||

Setting bandsaw blades | ||||

Thickness bandsaw blade min. | 0,5 mm | |||

Thickness bandsaw blade max. | 1 mm | |||

Width bandsaw blade min. | 10 mm | |||

Width bandsaw blade max. | 40 mm | |||

Setting pitch min. | 5 mm | |||

Setting pitch max. | 25 mm | |||

Setting speed | 107-162 teeth/ min | |||

Type setting A | ||||

Type setting B | ||||

Clearance angle min. | -5° | |||

Clearance angle max. | +18° | |||

Motor power | 2x0,18 kW 1x0,25 kW | |||

Wheel grinder dimension | 150x20x6 mm | |||

Machine dimension | B900xT700xH2600 | |||

Net weight | ca. 102 kg | |||

Packing dimension | B990xT810xH1720 | |||

Gross weight | ca. 159 kg |

Sharpening and setting machine TL-60 item-no.17505

Sharpening machine with setting machine. Inexpensive model. Automatic work cycle. Can sharpen bandsaw and circular saw blades and set bandsaw blades only. Can sharpen triangular profiles. Possbility to choose the sharpening: tooth front only or front and back. Allowing the independent adjustment of the feed pitch and combined adjustment of: working depth and entry/exit speed. It's vertical design was studied to require little space. Provided with rod and roller to support saw blades to be sharpened.

Technical data:

Sharpening bandsaw blade | Sharpening circular saw blades | |||

Teeth profile | Triangular | Teeth profile | Dreieckig | |

Thickness bandsaw blade min. | 0,5 mm | Thickness circular saw blade min. | 1 mm | |

Thickness bandsaw blade max. | 1,5 mm | Thickness circular saw blade max. | 3 mm | |

Width bandsaw blade min. | 10 mm | Boring circular saw blade min. | 20 mm | |

Width bandsaw blade max. | 60 mm | Boring circular saw blade max. | 50 mm | |

Sharpening pitch min. | 5 mm | Diam. circular saw blade min. | 110 mm | |

Sharpening pitch max. | 16 mm | Diam. circular saw blade max. | 600 mm | |

Sharpening speed | 23 teeth/ min | Sharpening pitch min. | 5 mm | |

Sharening pitch max. | 15 mm | |||

Sharpening speed | 54 teeth/ min | |||

Setting bandsaw blades | ||||

Thickness bandsaw blade min. | 0,5 mm | |||

Thickness bandsaw blade max. | 1 mm | |||

Width bandsaw blade min. | 10 mm | |||

Width bandsaw blade max. | 45 mm | |||

Setting pitch min. | 5 mm | |||

Setting pitch max. | 25 mm | |||

Setting speed | 107-162 teeth/ min | |||

Type setting A | ||||

Type setting B | ||||

Clearance angle min. | -0° | |||

Clearance angle max. | +15° | |||

Motor power | 1x0,18 kW 1x0,25 kW 0,09 kW | |||

Wheel grinder dimension | 150x20x6 mm | |||

Machine dimension | B820xT700xH2600 | |||

Net weight | ca. 67 kg | |||

Packing dimensions | B990xT810xH1720 | |||

Gross weight | ca. 124 kg |

|

Setting machine for bandsaw blades SV-80 MN item-no. 17506

Manual setting machine for bandsaw blades. Inexpensve and easy-to-use. Possibility to choose the setting: left/right or left/right/straight. Adjutment of the feed pitch, of the setting height and of the tooth bending degree. Workbench model.

Technical data:

Width bandsaw blade min. | 10 mm |

Width bandsaw blade max. | 80 mm |

Thickness bandsaw blade min. | 0,5 mm |

Thickness bandsaw blade max. | 1,2 mm |

Setting pitch min. | 5 mm |

Setting pitch max. | 35 mm |

Type setting A | |

Type setting B | |

Dimensions | B350xT400xH250 mm |

Net weight | 7 kg |

Packing dimensions | B350xT230xH250 mm |

Gross weight | 9 kg |